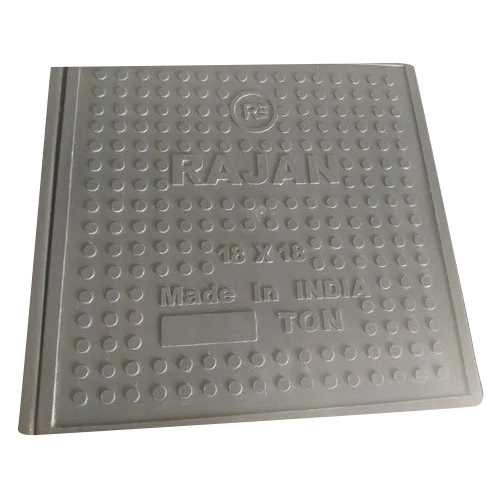

FRP Manhole Cover With Frame

FRP Manhole Cover With Frame Specification

- Shape

- Square

- Material

- FRP

- Dimensions

- 18x18 Inch Inch (in)

- Weight

- Differ as per size Kilograms (kg)

FRP Manhole Cover With Frame Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About FRP Manhole Cover With Frame

An FRP Manhole Cover with Frame typically includes the following components and features, designed for durability, load-bearing, and resistance to corrosion, especially in harsh or chemically aggressive environments:

Components of an FRP Manhole Cover with Frame:

-

FRP Manhole Cover (Lid):

-

Made from Fiber Reinforced Plastic (FRP) a composite material of resin (like polyester or epoxy) reinforced with glass fibers.

-

Can be circular, square, or rectangular depending on application.

-

Non-corrosive, non-conductive, and lightweight compared to cast iron or concrete.

-

Load rated (e.g., A15, B125, C250, D400) as per EN 124 standards.

-

-

FRP Frame (Rim/Base):

-

Supports the cover and distributes load to the surrounding surface.

-

Also made of FRP or in some cases, cast iron for added strength.

-

Fixed into concrete or pavement.

-

-

Locking Mechanism (Optional):

-

Some models include locking bolts or latches to prevent unauthorized access or theft.

-

Tamper-proof designs are available.

-

-

Sealing Gasket (Optional):

-

Rubber or neoprene gasket for watertight or odor-proof sealing.

-

Often used in sewage or telecom applications to prevent water ingress or gas leakage.

-

-

Lifting Keyholes or Handles:

-

Moulded-in or built-in keyholes to lift the cover using standard tools.

-

Some may have embedded metal parts to reinforce these areas.

-

Design Features:

-

Slip-Resistant Surface: Anti-skid design (textured or patterned).

-

UV Stabilized: Suitable for prolonged outdoor exposure.

-

Chemical Resistant: Suitable for sewer lines, chemical plants, etc.

-

Non-Sparking & Non-Conductive: Ideal for electrical or explosive environments.

Typical Applications:

-

Sewer and drainage systems

-

Telecom and electrical manholes

-

Utility vaults

-

Roadways, sidewalks, and industrial plants

-

Gas and water pipelines

Would you like a comparison between FRP and traditional manhole covers (like cast iron or concrete), or a technical drawing/specification sheet?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Manhole Cover Category

FRP Blue Manhole Cover

Minimum Order Quantity : 100 Units

Shape : Square

Application : Water Supply, Drainage

Material : FRP

Load Capacity : 5 Tonne

Weight : Differ as per size Kilograms (kg)

FRP Round Manhole Cover

Minimum Order Quantity : 100 Units

Shape : Round

Application : Water Supply, Drainage

Material : FRP

Load Capacity : 5 Tonne

Weight : Differ as per size Kilograms (kg)

FRP Square Manhole Cover

Minimum Order Quantity : 10 Units

Shape : Square

Application : Water Supply, Drainage

Material : FRP

Load Capacity : up to 50 Tonne

FRP Rectangular Manhole Cover

Minimum Order Quantity : 10 Units

Shape : Other, Rectangular

Application : Water Supply, Drainage

Material : FRP

Load Capacity : 12.5 Tonne

Weight : Differ as per size Kilograms (kg)

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese