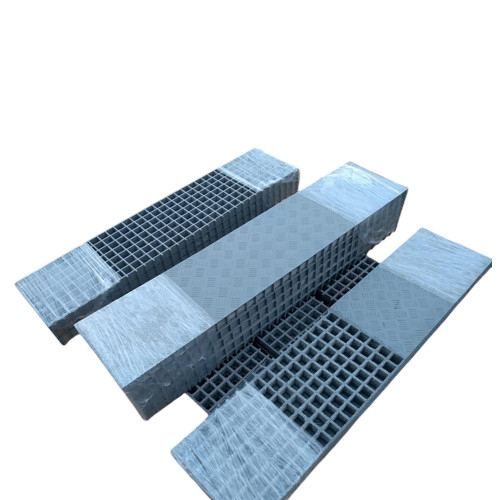

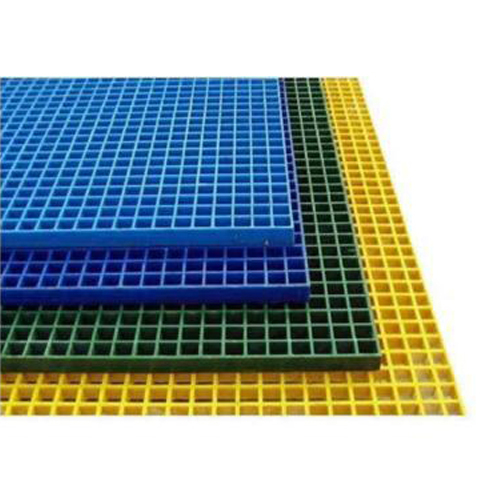

FRP Moulded Gratings

Price 2450 INR/ Piece

FRP Moulded Gratings Specification

- Shape

- Rectangle

- Usage

- Walkways and Platforms, Etc

- Material

- FRP

- Application

- For Industrial Use

- Size

- Different available

- Color

- Grey

FRP Moulded Gratings Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 5000 Pieces Per Day

- Delivery Time

- 2-3 Days

- Main Domestic Market

- All India

About FRP Moulded Gratings

An FRP Moulded Grating is a type of Fiber Reinforced Plastic grating formed by molding resin with fiberglass strands into a single-piece, grid-like structure. These gratings are widely used in industrial environments due to their corrosion resistance, strength, and non-conductive properties.

What FRP Moulded Grating Contains:

-

Resin Matrix (Thermosetting Resin):

-

Binds the fiberglass reinforcement.

-

Types of resins used (chosen based on environment):

-

Isophthalic Polyester Resin general chemical resistance

-

Vinyl Ester Resin high chemical and corrosion resistance

-

Orthophthalic Polyester Resin economical, moderate resistance

-

Phenolic Resin fire retardant and smoke suppressant

-

-

-

Fiberglass Reinforcement:

-

Continuous glass fiber rovings layered in both longitudinal and transverse directions.

-

Provides strength, load-bearing capacity, and structural integrity.

-

-

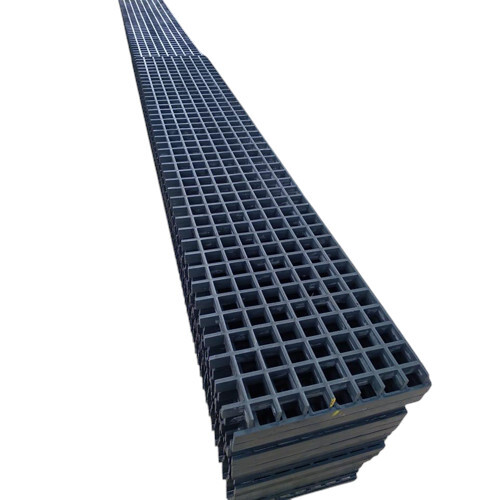

Moulded Grid Structure:

-

Formed by placing the fiberglass and resin mixture into a heated mold.

-

Cures into a one-piece panel with uniform distribution of resins and fibers.

-

Mesh types vary: square (standard), rectangular, mini-mesh, etc.

-

-

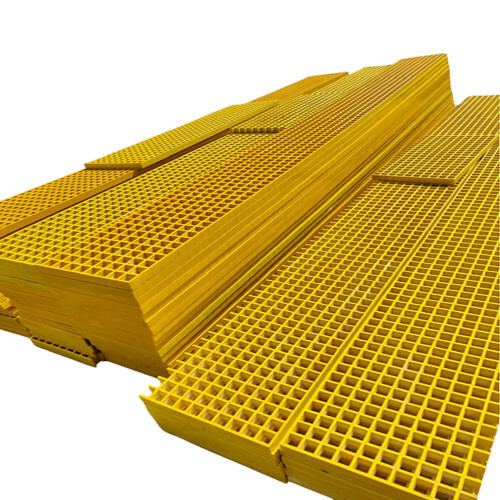

Surface Finish:

-

Anti-skid surface (commonly concave, grit top, or smooth).

-

Grit is usually silicon carbide or quartz, embedded during molding for slip resistance.

-

-

UV Stabilizers (Optional):

-

For outdoor use, UV inhibitors are added to protect against sun degradation.

-

-

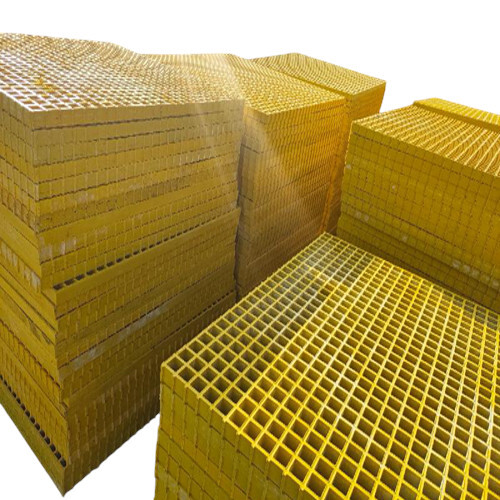

Color Pigments (Optional):

-

Pigmented throughout the thickness of the grating.

-

Common colors: yellow, green, grey, black.

-

-

Fire Retardants (Optional):

-

To meet fire safety standards like ASTM E84 or UL94.

-

Available Forms:

-

Panel Sizes: Commonly 1220x3660 mm (4x12) or custom sizes

-

Thicknesses: Typically from 25 mm (1) to 50 mm (2)

-

Mesh Sizes: e.g., 38x38 mm (standard), 19x19 mm (mini-mesh), etc.

Applications:

-

Walkways, platforms, and stair treads

-

Chemical plants and offshore rigs

-

Water treatment facilities

-

Battery rooms (non-sparking)

-

Cooling towers and trench covers

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Grating Category

FRP Walkway Grating

Price 4500 INR / Meter

Minimum Order Quantity : 100 Meters, ,

Surface Treatment : Polishing

Size : Different available

Product Type : Walkway Grating

Material : FRP

FRP Grating

Price 2370.00 INR / Square Meter

Minimum Order Quantity : 100 Square Meters

Surface Treatment : Galvanized

Size : Different available

Product Type : Grating

Material : FRP

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese